Bob's Bug - The Exodus and Bob's TO - DO List

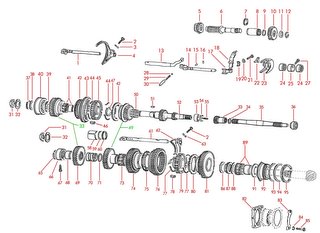

Saturday, April 22. 3 days after the original due date. I will be towing Bob's bug to Orillia today. It's been a fun experience taking this rough shell to a solid, safe vehicle. I am really surprised that it is actually done. The number of unexpected obstacles has been incredible: auto-stick to manual conversion, lower frame head installation, transmission reverse gear repair, Bob's Honda seats, Bob's refusal to do the wiring, troubles bleeding the brake system, and the list goes on.

The vehicle is being passed to Bob in running, driving condition. All the wiring is now functional, with the exception of the horn and rear window defroster. We may also need a replacement high / low beam relay, but this is rather insignificant in the grand scheme of things.

Here's a list of items Bob should complete, items for safety first, followed by other general items:

SAFETY RELATED:

- Repair horn button or install auxillary button. Simply connect one side of the switch to ground, and the other side to the brown wire near the fusebox. The horn and power supply provisions have been provided, per stock. If the original horn button is fixed, simply connect the two wires together near the fusebox - I will show you the details.

- Cut and install temporary steel covers over holes into passenger compartment

- Install heat ducts from heat exchangers to cabin, or install sheet metal covers over heat duct holes

- Install licence plate bulb

- Install headlight

NON-SAFETY RELATED:

- Install heat lever kits and connect heat from passenger compartment entry to heat channels, including cutting hole into channel for access

- Adjust choke, Adjust points, check timing (I'll loan my timing light), and go through 34 PICT 3 idle adjustment procedure to set carburetor

- drill, tap, and install front wheel centre caps

- remove, drill, tap, and reinstall rear wheel centre caps

- install door weather stripping

- install drivers window felt and weather stripping

That's all I can think of for now!